I see people saying that HLG 550 V2 is comparable to a 1k HPS single end, now if its true are no you suppose to harvest the same with both light let say if you use to have 1 gram per every watts of the 1k hps = 1000 grams then I believe that you are supose to have the same harvest with HLG 550 V2 that you have with hps single end.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HLG 550 V2 Vs 1K HPS Single end.

- Thread starter augusto1

- Start date

diggs99

Well-Known Member

Ya I think the 550 draws 485 from the wall.

I'm pretty sure I've seen a few.growers hitting 2g/w using qbs and strips? Can't say 100% tho. So at 2g/w they would be comparible to the 1k and using half the juice.

This is my first run with leds, I don't think I'll hit 2g/w but it's not gonna be far off.

I'm pretty sure I've seen a few.growers hitting 2g/w using qbs and strips? Can't say 100% tho. So at 2g/w they would be comparible to the 1k and using half the juice.

This is my first run with leds, I don't think I'll hit 2g/w but it's not gonna be far off.

hybridway2

Amare Shill

Should be pretty close . You gonna compare the 2?I see people saying that HLG 550 V2 is comparable to a 1k HPS single end, now if its true are no you suppose to harvest the same with both light let say if you use to have 1 gram per every watts of the 1k hps = 1000 grams then I believe that you are supose to have the same harvest with HLG 550 V2 that you have with hps single end.

PSUAGRO.

Well-Known Member

I see people saying that HLG 550 V2 is comparable to a 1k HPS single end, now if its true are no you suppose to harvest the same with both light let say if you use to have 1 gram per every watts of the 1k hps = 1000 grams then I believe that you are supose to have the same harvest with HLG 550 V2 that you have with hps single end.

Getting 1gpw of flower tops(no larf) from a SE thouie is not easy, regardless of what the internet tells you......yes, hlg 550 v2 is a swap generally speaking

You can diy a better strip light for cheaper if you have time to burn?

NanoGadget

Well-Known Member

I know things don't always scale in a linear fashion, but I run two QB 288 v2 @ ~230 watts and it consistently out performs the 400 watt hps that I used to run in the same space.

wietefras

Well-Known Member

A 1000W SE HPS is measured to emit about 1400umol/s out of the reflector. The 550 V2 is advertised to emit 1178umol/s. So, that's about a 20% difference in usable light.I see people saying that HLG 550 V2 is comparable to a 1k HPS single end

Thing is, in the US people tend to put a 1000W light in a 4x4. Which is really too small for that size light. This causes way to much light loss on the walls. The light will need to be put up extra high to prevent burning the plants, which increases the wall losses even further. After doing all that wrong, you will probably be left with the same amount of light from that HPS as from the leds.

Besides, it's a bit of a daft comparison. Who is dumb enough to use 1000W SE HPS still anyway? A double ended HPS gives you almost 25% more light per watt and then you would have 53% more usable light from the HPS as from the leds.

You would need about 720W of 2.5umol/J efficacy leds to produce the same amount of light as a proper 1000W HPS (DE).

If you were to build a 720W of 2.5umol/j efficacy what kind of leds (boards, cobs, strips) woud you use to build it? Thanks in Advance.You would need about 720W of 2.5umol/J efficacy leds to produce the same amount of light as a proper 1000W HPS (DE).

Yes I have the time to burn it, what would be the best strip to use? Thanks In Advance.Getting 1gpw of flower tops(no larf) from a SE thouie is not easy, regardless of what the internet tells you......yes, hlg 550 v2 is a swap generally speaking

You can diy a better strip light for cheaper if you have time to burn?

I just want to build them and I want to be pretty sure before I buy the materials to build them. ThanksShould be pretty close . You gonna compare the 2?

Yes I being watching your post, you are doing great job.Ya I think the 550 draws 485 from the wall.

I'm pretty sure I've seen a few.growers hitting 2g/w using qbs and strips? Can't say 100% tho. So at 2g/w they would be comparible to the 1k and using half the juice.

This is my first run with leds, I don't think I'll hit 2g/w but it's not gonna be far off.

it is good to know, ThanksI know things don't always scale in a linear fashion, but I run two QB 288 v2 @ ~230 watts and it consistently out performs the 400 watt hps that I used to run in the same space.

diggs99

Well-Known Member

Augusto,

Where are you located?

@Greengenes707 Pacific light concepts are selling the newest photoboost strips and they look good. Top bin diodes and slick heatsinking. Main issue here is I think he only ships inside the US.

@welight Cutter is also selling some high end strips too. Osram and nichia

@Prawn Connery is selling those crazy ass qbs they made , putting out very good numbers

There's a few ways you can build and have it put out the numbers you want.

Where are you located?

@Greengenes707 Pacific light concepts are selling the newest photoboost strips and they look good. Top bin diodes and slick heatsinking. Main issue here is I think he only ships inside the US.

@welight Cutter is also selling some high end strips too. Osram and nichia

@Prawn Connery is selling those crazy ass qbs they made , putting out very good numbers

There's a few ways you can build and have it put out the numbers you want.

http://ledgardener.com/diy-led-strip-build-designs-samsung-bridgelux/

Just some of the companies with LED boards/strips in the 2.5umol/J range....

https://diyleduk.com/

https://atreumlighting.com

https://horticulturelightinggroup.com

www.bcblondes.com

www.pacificlightconcepts.com

www.cutter.com.au

Some of the big commercial names for white light without added reds etc....

Samsungs F-series and H Influx.

Bridgelux EB series.

https://www.led-tech.de/en/50cm-Alustripe-with-98x-Samsung-LM301B-LEDs-3500k

https://www.led-tech.de/en/ZEUS-308-XT-High-Performance-KIT-3500k

Just some of the companies with LED boards/strips in the 2.5umol/J range....

https://diyleduk.com/

https://atreumlighting.com

https://horticulturelightinggroup.com

www.bcblondes.com

www.pacificlightconcepts.com

www.cutter.com.au

Some of the big commercial names for white light without added reds etc....

Samsungs F-series and H Influx.

Bridgelux EB series.

https://www.led-tech.de/en/50cm-Alustripe-with-98x-Samsung-LM301B-LEDs-3500k

https://www.led-tech.de/en/ZEUS-308-XT-High-Performance-KIT-3500k

Last edited:

Prawn Connery

Well-Known Member

They would look almost exactly like this: two double High Light boards with heatsinks each driven by a HLG-320H-48A producing 350+W at the boards (700+W total) at 2.5 umol/j efficiency with a bit of bonus UVA.If you were to build a 720W of 2.5umol/j efficacy what kind of leds (boards, cobs, strips) woud you use to build it? Thanks in Advance.

Prawn Connery

Well-Known Member

wietefras

Well-Known Member

I use led strips. In my Case Samsung F-series Gen 3, but here are plenty of options. Indeed summed up mostly by 1212hamIf you were to build a 720W of 2.5umol/j efficacy what kind of leds (boards, cobs, strips) woud you use to build it?

Led strips gives a better light distribution compared to quantum boards too. Which allows you to hang the fixture lower and then lose less light on the walls (while keeping the same light uniformity). This lower loss of light on the walls can help another 10% to 20% with total amount of light on the plants.

wietefras

Well-Known Member

Wow, I missed that chart above before. So you pump in 1750umol over 4x4 (=about 1200umol average per m2) and then you are left with an average of only 826umol/s/m2? Which means that only 70% of the light actually reaches the plants. The rest is wasted on the walls because it hangs so high (40cm).

That's why I prefer strips over boards. Hang 8 separate 112cm strips and you can hang the light at 20cm (actually less even). Saves you half the wall losses. Actually 4 strips would already be sufficient to cut the hanging height in half compared to the boards.

Which means that 600W of strips will give you the same amount of photons on the plants as you get from 700W of boards!

That's why I prefer strips over boards. Hang 8 separate 112cm strips and you can hang the light at 20cm (actually less even). Saves you half the wall losses. Actually 4 strips would already be sufficient to cut the hanging height in half compared to the boards.

Which means that 600W of strips will give you the same amount of photons on the plants as you get from 700W of boards!

Last edited:

Prawn Connery

Well-Known Member

Let's not be dishonest here – you can throw as many LED boards as you can fit in a 4'x4' and realise much better efficiency. That's the first point.Wow, I missed that chart above before. So you pump in 1750umol over 4x4 (=about 1200umol average per m2) and then you are left with an average of only 826umol/s/m2? Which means that only 70% of the light actually reaches the plants. The rest is wasted on the walls because it hangs so high (40cm).

That's why I prefer strips over boards. Hang 8 separate 112cm strips and you can hang the light at 20cm (actually less even). Saves you half the wall losses. Actually 4 strips would already be sufficient to cut the hanging height in half compared to the boards.

Which means that 600W of strips will give you the same amount of photons on the plants as you get from 700W of boards!

The second point is, when LED manufacturers calculate efficiency, they do it at a set current: commonly 65mA for 3V mid-power (3030) LEDs. So here is an efficiency test on our boards at roughly that level. This test also directly correlates to two more PAR maps I have calculated below.

2.47 umol/j at 1.5A.

The PAR map in the previous post (August 2019) was for four boards at 3.5A per board (as you can see in the Dialux program top left). At that much higher current, the boards have been tested at 2.17 umol/j – so your calculation is not correct (there appears to be another issue with your calucation, but I'm sure you'll work it out).

I can see how you would have assumed they were running at 2.5 umol/j and not 2.17, because of the ambiguity surrounding "advertised" efficiencies vs efficiencies at higher currents. So I will take the blame for that. I simply posted a real-world example of four boards in a 4x4 running at 676W at 2.17 umol/j. I didn't know it was going to be dissected by you. After all, you've had me on ignore for a long time – haven't you?

Here are eight boards over the same area at 1.5A per board (560W total) at 40cm at 80% wall reflectivity – these boards are running at a true 2.47 umol/j:

Here is the same configuration at 20cm:

So at 40cm, 560W of LED boards is producing an average of 1023 PPFD and at 20cm it is 1150 PPFD. What's more, if you were running CO2, your plants would be right in the Goldilocks zone under even the hottest spots produced by the boards at 20cm (1350 PPFD). But if you weren't, you would run them at 40cm – because the average PPFD might be slightly lower (down 11%), but the coverage is more even.

It's still more efficient than your strips, and I guarantee the boards provide more even coverage. At least, based on what you have written, because you haven't posted a PAR map of your own set-up yet.

Of course, you can also play around with the board configuration (move them closer together) to get higher average PPFD readings, but you lose the even coverage and introduce more hot-spots. With strips, you are always going to have hotspots directly under each strip at such low hanging heights, and the only way to prevent that is to move the strips closer together – much like a board(!).

If we ever get to see your PAR maps, that's probably what we will see.

ChiefRunningPhist

Well-Known Member

A side by side would provide some evidence to anyone's claims otherwise it's just a bunch of estimated guesses.I see people saying that HLG 550 V2 is comparable to a 1k HPS single end, now if its true are no you suppose to harvest the same with both light let say if you use to have 1 gram per every watts of the 1k hps = 1000 grams then I believe that you are supose to have the same harvest with HLG 550 V2 that you have with hps single end.

HPS have different spectrums than LEDs, and LEDs have different spectrums than other LEDs. When you compare only the μmol/s output of 2 lights, you're not controlling for spectrum which has a huge impact on growth and on the possible efficiency of the light.

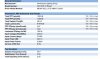

Heres some lights that were tested in 2017, I wouldn't count on many lights hitting 2.5+, ime advertisers drastically over promise because they know you'll not pay to have them tested...

If you're going strictly by quantity of photons, the hlg 550 pushes 1,293μmol/s (tested by 3rd party, so no reason to distrust), and looking at the data an average 1000W SE HPS (USHIO 5001671, for example) would push ~2,000μmol/s.

If quantity of photons is the only factor then a 1000W HPS will produce ~1.5× more plant than an HLG 550, but imo spectrum plays a huge roll and so a side by side would be a more effective way at determining what the implications are, I've not seen one done yet.

Attachments

Last edited:

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 71

- Views

- 9K

- Replies

- 1

- Views

- 461