SupraSPL

Well-Known Member

It is a stinker, coffee + OG cologne, good potency, bud density and plant structure, mold resistant, one of my favorites maybe top 10 out of 200.That Alien looks great!

I have bought 2 heatsinks 5.88" x 19" so I can put 2 cobs on each one. My question is regarding the spacing of the cobs on each heat sink.

I noticed you installed the cobs closer to the corners on one more than on the other. Does this help,hurt, or make any difference at all in temp. control. What would you recommend the distance be on my set up from cob to cob and the edge of the heat sink?

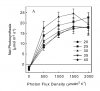

Yes I think when push comes to shove uniformity of PPFD is more important. Poor temp distribution in your heatsink might cost you only 1% total output but poor uniformity could potentially cost much more

You can have it both ways but it requires playing around with heatsink profiles. This is a 2' X 6' with the heatsinks also to scale. Based on this I would suggest mounting the COB close to the edge or even slightly diagonally if necessary.