Rahz

Well-Known Member

Those would be perfect except the center doesn't fully cover the 3590. Mounting issues and possible thermal issues.

That's not the answer I was looking for. Basically any heat sink can dissipate 80W. The question is how will it's temperature rise in common ambient temp (25°C).It means they have a thermal Capacity to dissipate 80 watts, so a 3590 at 50%+ eff would be less than 40 watts, so the cooler has twice the capacity than required

Cheers

Mark

He gave the thermal resistance(0.5942 DegC/W). It's all you need to know.That's not the answer I was looking for. Basically any heat sink can dissipate 80W. The question is how will it's temperature rise in common ambient temp (25°C).

He gave the thermal resistance(0.5942 DegC/W). It's all you need to know.

Ex

cxb3590@80w=~45% efficient...so 44w of heat

Ideal temp rise=...50c(desired)-25c(ambients) = 25∆

25(temp rise)÷44w(heat)=.57c/w

subtract the thermal interface ~.5-1

~0.5c/w is what is need for a 3590 at 80w.

That heatsink should keep temps pretty good even at 80w with a 3590. Anything less efficient will suffer more temp droop.

I would be willing to buy these if you can source them. Pre-drilled would be nice but I could do it myself if necessary. Anodized would also be nice, but also not absolutely necessary

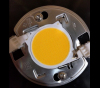

View attachment 3601667

Yes, 50c is a preference. And for passive or even enclosed active are awesome numbers. 55c is what I deem my point for under 70w power. That will provide basically affected output over it's life. Over that(75w+) I accept ~60-65c and faster degradation as well as lower performance.@Greengenes707

I like your 50c. Just your preference I assume.

Anything after 50C gets a little hot to touch and could result in higher temp droops.

I think the industry standard is like 85C

But its too high. I consider max 60C to try and keep case temps under 75C

What I don't know is where is this temp measured. If we know with thermal resistance that heatsink should be 50C. Is this the hottest part of heatsink or average.

I mount thermocouples directly behind or adjacent to cob. Within 10mm from heat source.

Welcome. And yes I did mean that. Edited now, thanks.Thanks GG for the math.( you write TIM ads .5 -1 to thermal resistant but from the math i think u meant .05 -.1 pleas correct me if im wrong)

so if i understand than for cxb 3590cd with low quality TIM at 49w the math wold be;

49(w) x .44(heat w) x .69(thermal resistent 0.59+0.1 for the tim)=14.87(celsius temp rise above ambient)

Is this correct?